- Teknolojik Çözüm Ortağınız... / Your Technological Solution Partner...

Plasma Cutting Machines | EFE CNC

- Home

- Advanced Cutting Technologies

- Plasma Cutting Machines

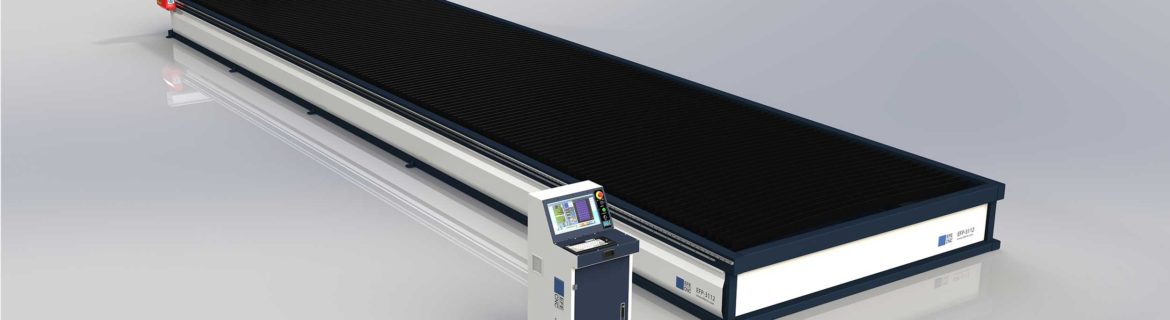

Plasma Cutting Machines:

Technological Advantages and Features

Plasma cutting machines play a crucial role in industrial production processes and stand out with their technological advantages. Especially due to their superior features in precision, energy efficiency, and durability, they are widely used in modern manufacturing facilities.

Precision Cutting and High Durability

Plasma cutting machines are highly effective in providing precise cuts. This technology enables high accuracy and quality results, especially in metal processing. The machine’s robust construction and high durability ensure long-lasting performance and reliability even under heavy usage conditions.

Energy Efficiency and Technological Equipment

Plasma cutting machines offer the advantage of reducing costs through low energy consumption. The high-tech equipment used in modern plasma cutting machines makes cutting processes faster, better, and more precise. These technologies enhance efficiency by saving time and materials in the production process.

Advanced Features and Automation

Today’s plasma cutting machines are equipped with a Windows-based CNC control unit, allowing users to easily control the machine’s speed and precision. The dual-side drive and helical rack-and-pinion drive system provide high speed and precise positioning. Additionally, features such as automatic torch height control and waste-free part placement contribute to material and time savings.

Additional Safety and Cleaning Systems

The machine’s collision safety system and cutting table with air/water cleaning systems enhance safety and cleanliness standards. AC servo motors provide precision in axial movements, while automatic gas control supports operational safety.

In conclusion:

Plasma cutting machines offer high performance and efficiency in industrial production processes. With their precision cutting, low energy consumption, and durability, these machines provide effective solutions for modern manufacturing needs. For more information and product details, you can contact us.

You can call us : +90 530 283 53 38

You can write to us on WhatsApp : +90 530 283 53 38

or If you fill out the Contact form, we can call you.

Post your Comments