- Teknolojik Çözüm Ortağınız...

- info@efecnc.com

- +90 530 283 53 38 |

|

|

Plazma Kesim Videoları

EFE CNC Plazma Boru ve Profil Kesim

EFE CNC Plazma ve 3D Boru Kesme

EFE CNC 3D Plazma Kesim THC Test

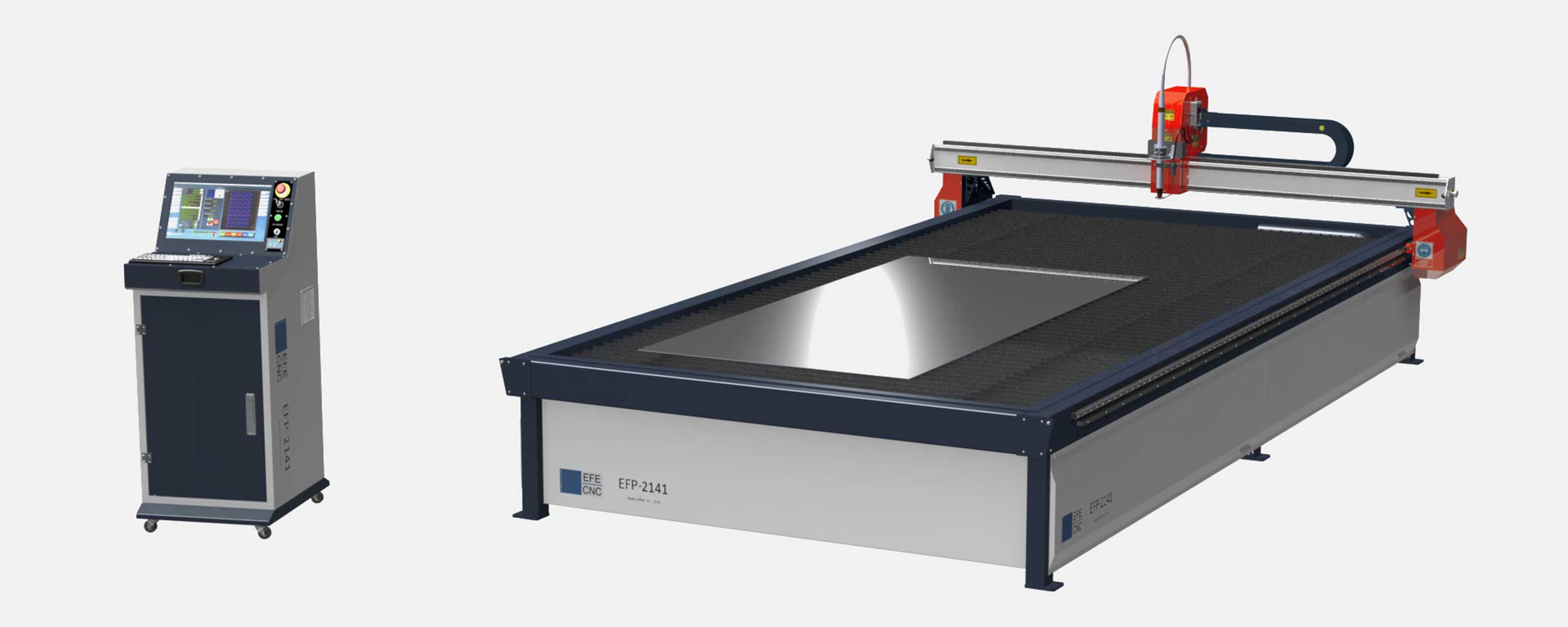

EFP-2141 CNC Plazma ve Entegre 3D Boru Kesme

Sac Kesim Alanı (2000x4000mm) –

Boru Kesim Ölçü(1300mm uzunluk 100-600mm çap)

EFP-6020 CNC Plazma Boru & Profil Kesim Makinesi

CNC Plazma Boru ve Profil Kesim (6000 mm uzunluk ve 20-200 mm çap)

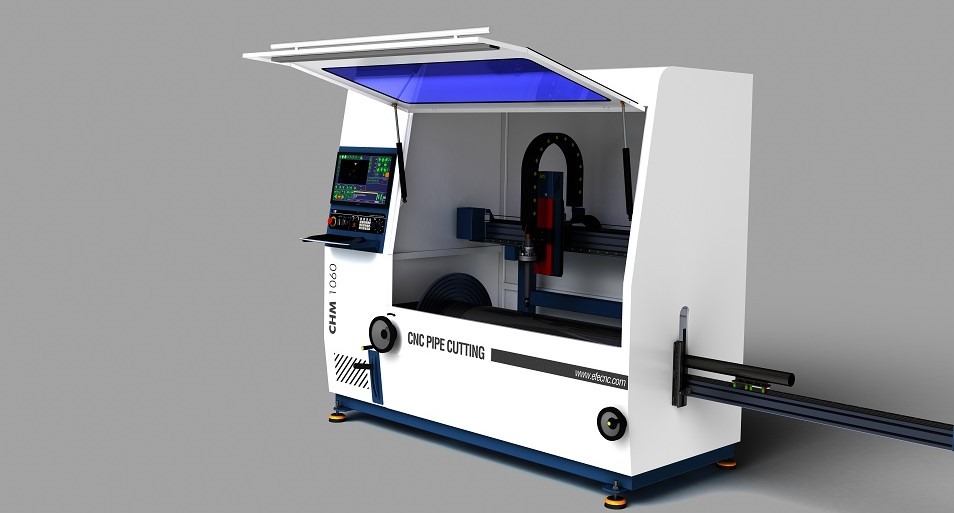

CHM-1060 CNC Plazma 3D Boru Kesim Makinesi

100 x 600 mm çap ve 1200 mm uzunluğunda baca boruların kesimi için.

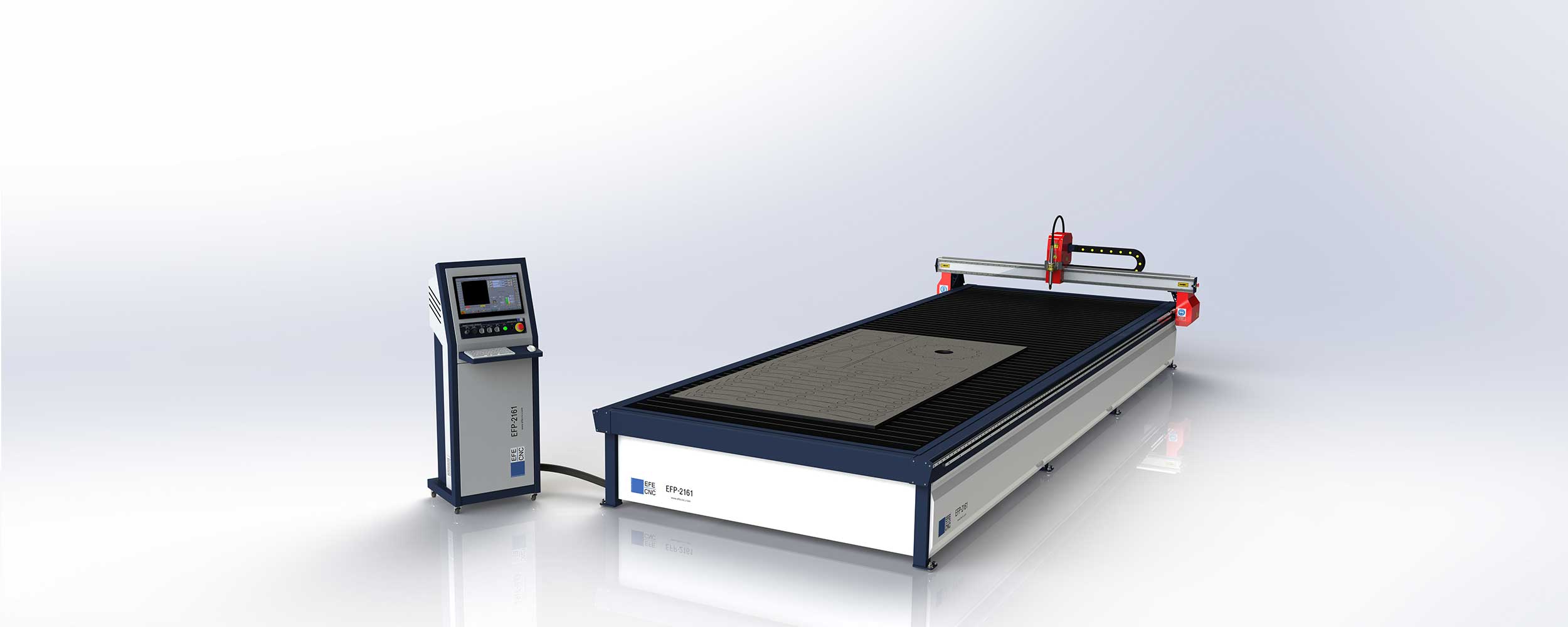

EFP-2161 CNC Plazma ve Entegre 3D Boru Kesme

Sac Kesim Alanı (2000x6000mm) –

Boru Kesim Ölçü (20-200 mm çap ve max. 6000 mm uzunluğundaki boru)

Neden EFE CNC Plazma Çözümleri?

-

Kolay Kullanım

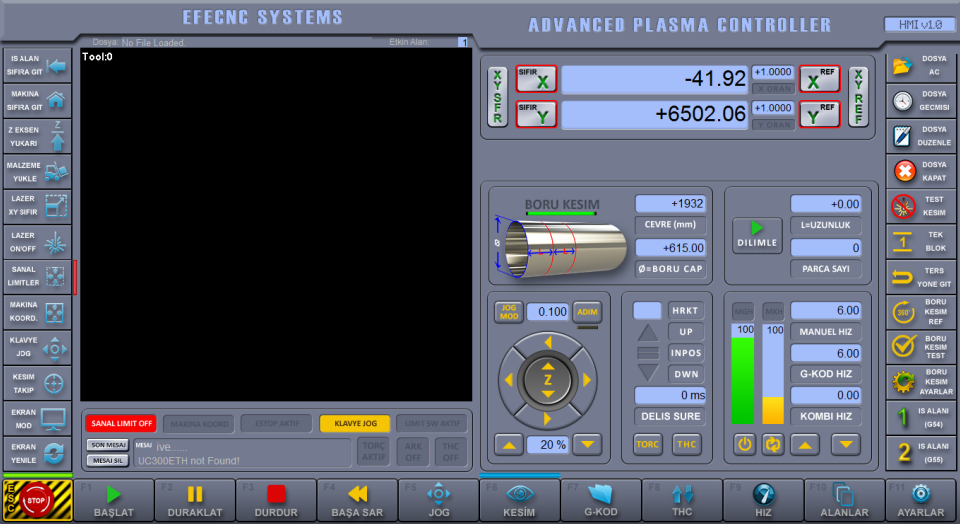

EFE CNC, hem donanım hem de yazılım olarak kullanıcı dostu özellikler taşır. Windows tabanlı Türkçe CNC kontrol yazılımı ve otomatik torç yükseklik kontrolü bunlardan sadece birkaçı.

-

Hassas ve Hızlı Kesim

EFE CNC, sahip olduğu bilgi birikimini üretime yansıtarak işiniz için en kaliteli ürünleri sunar. Kesim kalitesiyle lazer kesim makinelerine yakın kesim kalitesi sunan EFE CNC, bunu yaparken performansını da korur.

-

Kaliteli Komponentler

EFE CNC, sizin için en kaliteli bileşenleri bir araya getirerek sunar. İleri teknoloji çözümler sunan EFE CNC plazma ünitesi olarak ise dünyanın önde gelen üreticilerinden Hypertherm ile çalışmaktadır.

-

Uygun Fiyat

EFE CNC, hem yatırım hem de işletme maliyetlerinizi düşürerek alırken kazandırmaya başlar. Yurt içi ve yurt dışı emsallerine oranla daha uygun fiyatlarla sahip olabilceğiniz makinelerimiz ile kesim kalitesinden de taviz vermezsiniz.

-

7/24 Teknik Destek

EFE CNC, satış sonrası hizmetleriyle de tercih edilen bir konumdadır. Satış sonrasında makineye dair oryantasyon eğitimini veren uzman kadromuz bunun yanı sıra yaşanabilecek öngörülemeyen sorunlar için de sürekli yanınızda.