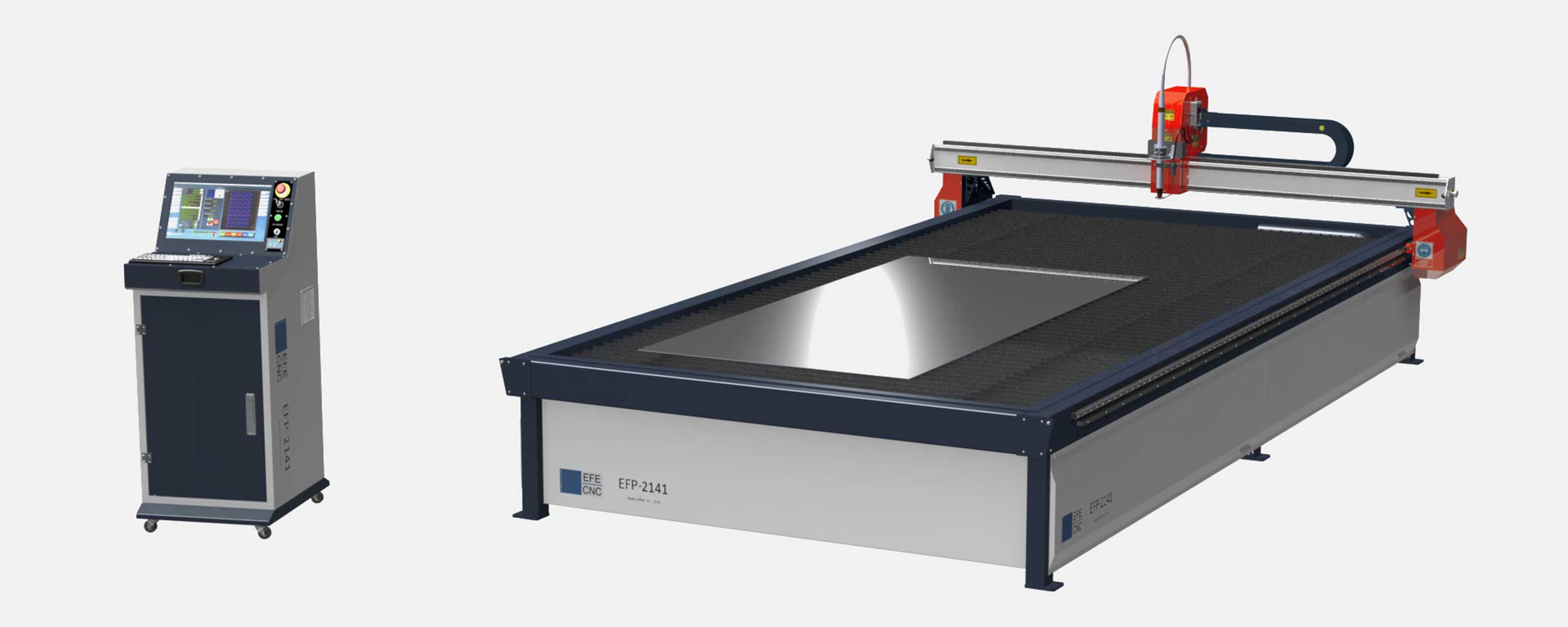

Wide Cutting Capacity

The EFP-1631 CNC Plasma Cutting Machine is specially designed for cutting metals with dimensions of 2000 x 4000 mm. This expansive cutting area allows for precise and efficient cutting of metal plates in various sizes and thicknesses. The machine’s large working space offers high efficiency and flexibility in industrial applications, enabling you to handle large-scale projects with ease.

Superior Performance in Metal Cutting

The EFP-1631 is equipped with high-performance plasma cutting technology. This technology enables you to cut various types and thicknesses of metal quickly and accurately. It delivers near-laser quality cutting results, ensuring high precision and clean surfaces. This feature provides significant advantages, particularly in detailed and complex metal processing projects.

Industrial Quality and Durability

The machine is manufactured with industrial-grade, durable components. High-quality materials and a robust structure ensure that the EFP-1631 delivers long-lasting and reliable performance. Its low-maintenance design reduces operational costs and minimizes downtime in your production processes.

Various Application Areas

The EFP-1631 is suitable for a wide range of applications, from metal processing workshops to large industrial production facilities. Whether for small-scale projects or large-scale production needs, this machine offers flexible and effective solutions. Its high efficiency in cutting metal plates meets various job requirements.

Conclusion

In summary, the EFP-1631 CNC Plasma Cutting Machine optimizes your metal cutting processes with its wide cutting dimensions and superior performance. It provides an excellent solution for metal cutting needs of 2000 x 4000 mm dimensions and ensures high efficiency in your industrial production processes.