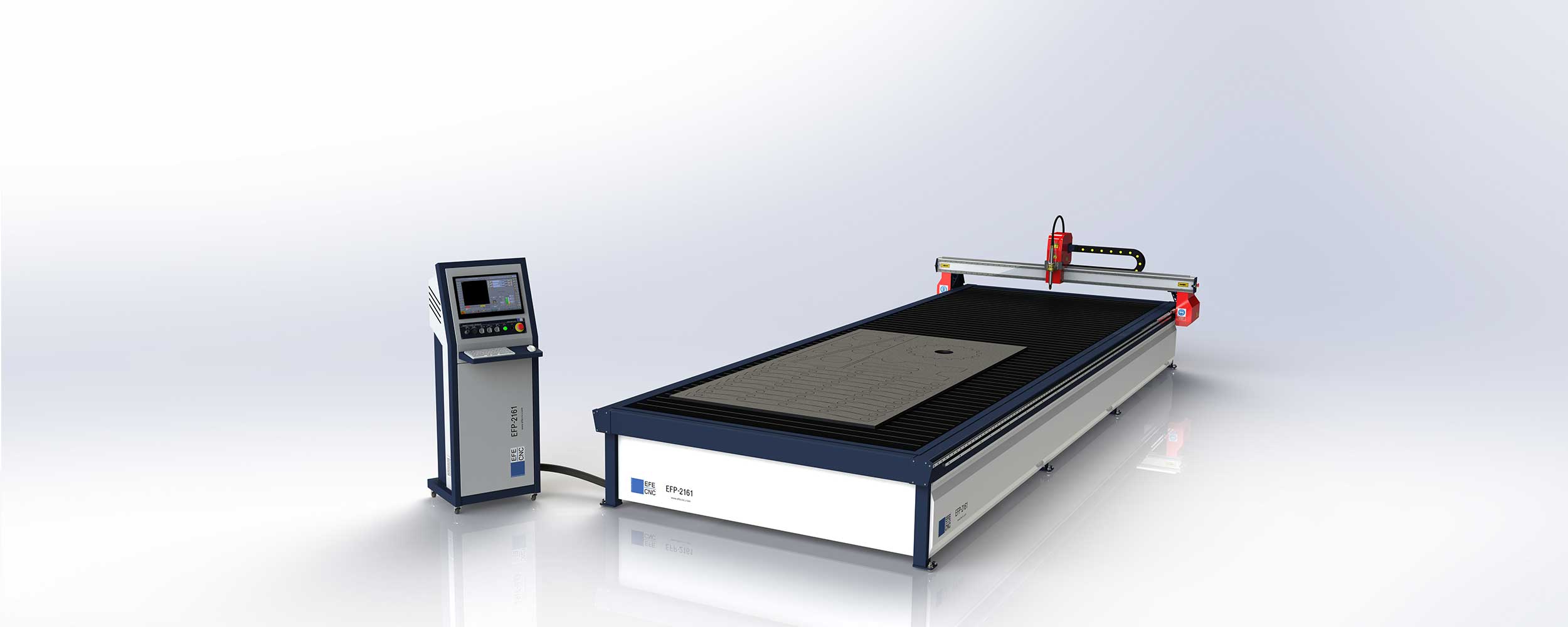

Wide Cutting Capacity

Designed for 2000 x 6000 mm dimensions, this cutting machine is an excellent solution for cutting all types of metal. The large cutting area allows for processing metal sheets of various sizes and thicknesses, making it an ideal choice for large-scale projects and diverse industrial applications.

High Performance and Flexibility

The machine is developed to meet your metal processing needs to the highest standards. Its large dimensions provide high performance for both small and large-scale projects. Additionally, the flexibility offered by the machine allows for working with different types and thicknesses of metal, enhancing project flexibility and efficiency.

Advanced Technology and Precision

The advanced technology of the machine enables precise and rapid cutting of various types and thicknesses of metal. High accuracy cutting features facilitate the perfect processing of complex geometric shapes and details. This enhances quality in metal processing projects and provides significant advantages in your work processes.

Ease of Use and Efficiency

The user-friendly design of the machine allows operators to manage cutting operations easily. The simple and intuitive control panel speeds up adjustments and programming processes, saving time in production and increasing overall efficiency. Additionally, its durable and long-lasting construction reduces maintenance costs and minimizes downtime.

Conclusion

In conclusion, this metal cutting machine, designed for 2000 x 6000 mm dimensions, is an excellent choice with its high performance, wide dimensions, and precision features. It is ideal for achieving superior results in both small and large-scale projects. You can use this machine to make your metal cutting processes more efficient and effective.