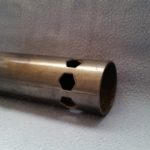

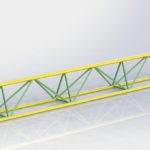

This model, integrated into the CNC Plasma Cutting Table, is designed for cutting pipes with a thickness of 5-10 mm and a maximum diameter of 200 mm, as well as profiles with maximum dimensions of 150 x 150 mm square, 150 x 200 mm rectangular. All axes are driven by maintenance-free AC servo motors. The machine is equipped with a ready-to-use air filtration system to remove cutting smoke from the environment. The compact system provides maximum efficiency with less space and a lower initial investment cost.

- Teknolojik Çözüm Ortağınız... / Your Technological Solution Partner...

EFP-2161 Integrated CNC Plasma Sheet and Pipe Cutting Machine

PRODUCT IMAGES

PLASMA BRAND OPTIONS

TECHNICAL SPECIFICIATIONS

- 18″ color LCD screen

- Operator panel independent of the table

- Windows-based CNC control unit

- File transfer via USB and network connection

- 3D simulation before cutting

- PC-independent motion controller

- Material angle detection feature

- Fast loading feature with material load command

- Integrated voltage THC software in the interface

- Material cutting adjusted to different sizes with auto ratio

- Online support and service

- Compatibility with software drawings such as CorelDraw, AutoCAD, and SolidWorks

- EFE CNC Turkish-English CNC interface program optimized for CNC plasma cutting

- Licensed, continuously updated nesting software that converts many program formats to G codes

- Ability to generate reports on cutting time, number of piercings, cutting distance, and cutting settings

- Ability to view potential errors with 3D simulation before cutting

- More precise and high-quality holes with software intervention in hole cutting speeds

- Option to create a cutting library for standard parts

- 20 m/min positioning speeds

- Laser Pointer

- Laser plate angle detection

- Higher quality cuts due to lightweight and rigid bridge design

- Precision linear rails on all axes

- Precision and clean cuts even on 0.5mm thin materials with a water-cooled table

- Extremely precise cutting and high cutting speed with advanced plasma power sources

- Ability to resume cutting from where it left off

- AC Servo or Easy Servo motors available on all axes, upon request

- Precision and durable rack and pinion drive system on A-Y axes

- Option to choose between helical rack or timing belt systems for smooth movement on the X axis

- Torch protection sensor on the Z axis against collisions

- EFE CNC automatic torch height control

SAMPLE CUTS

You can call us at: +90 530 283 53 38

You can also text us on WhatsApp: +90 530 283 53 38

Or, if you fill out the Contact Form, we can call you back.